Operation

The whole network of complicated routes is now run by an automatic computer and the fully-interlocked ex-BR lever frame in Maryloo Signal Box. The complex system is one of the most advanced model railway control systems in the world (without wanting to boast) but we’re rightfully proud of our train set. It’s a fusion of 1930s mechanics, 1970s resourcefulness and 21st Century digital technology.

Video: A guide to the operation, construction and maintenance of the Bekonscot Model Railway from the 1990s. Not much has changed – the railway is a bit larger now and we’ve more trains. But the principles remain the same. You’ll see how we clean the tracks, run the stock – and see a driver’s eye view of part of the circuit. Some colour fading on this (sorry!) but we’re working to restore the tape properly.

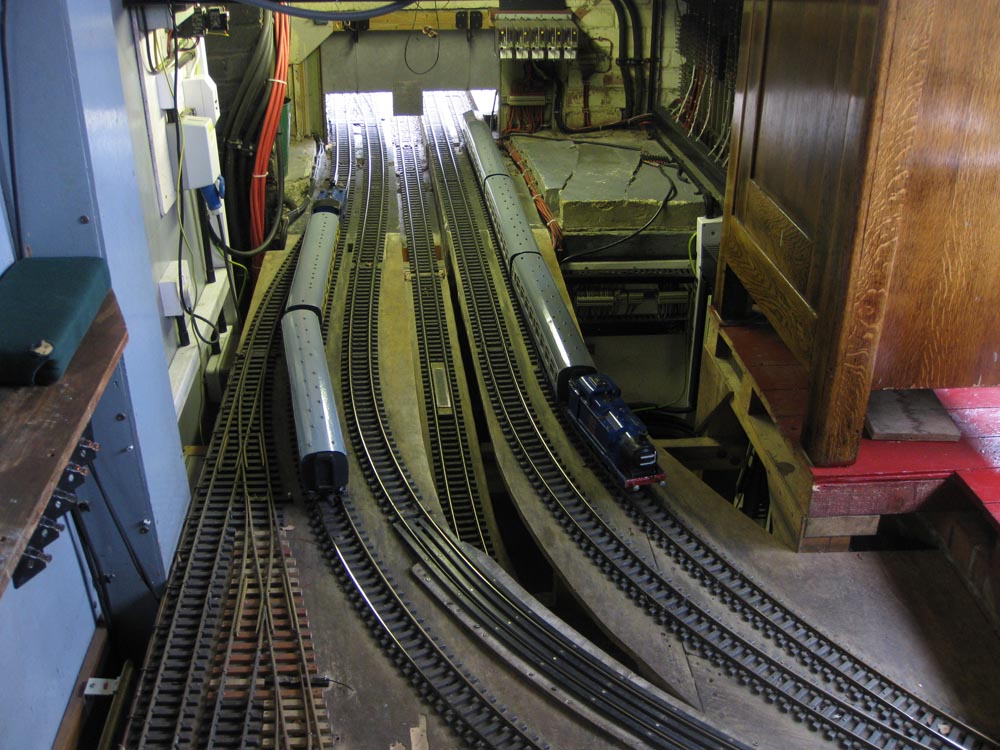

Maryloo Signal Box and Relay Room (the green building to its side) is the hub of all Bekonscot’s technology. The working Westinghouse ‘L’ lever frame came from Purley Signal Box on British Railways Southern Region and is backed up by an automated computer control system. The frame can be used by the Signalman to operate the tracks and signals around Maryloo, while outlying parts of the network are managed by the computer. The second lever frame (a Westinghouse ‘N’ style frame) is from Ruislip Gardens on London Underground.

Download a map of the Bekonscot Model Railway

Between the frames and running lines is a Relay Cabinet. In here, you can see the relays switching current between sections of track and signals, as the trains rattle around outside.

The computer system has been programmed by an expert Railway Software Engineer, who later went on to develop signaling for London’s Jubilee Line Extension.

The trains can be pre-set on their own routes for the day, obeying rules appropriate to their type – but can be overridden by the Signalman manually on the lever frame or by altering the computer settings. Goods trains and expresses use passing loops to bypass platforms, whilst local passenger trains are sent off to stop everywhere across this massive garden railway.

Some trains will use the Evenlode branch, whilst others don’t fit the tight tunnels. The computer develops the routes intelligently throughout the day to ensure that the model railway keeps running as it should.

Each train set has a tiny radio beacon inside it to allow the computer to confirm its identity, location and speed. The line is broken down into three big chunks: Red Mainline (anti-clockwise), Blue Mainline (clockwise) and the Blue Loop (the branchline to Evenlode coal mine). Each are over 150m long. To exchange trains between Red and Blue, they can be sent off down the loop and then back on to the other line in the opposite direction, or switched manually at Maryloo. Take a look at the trackplan for more information.

When not maintaining the garden railway routes or stock, the Signalmen can often be found to be controlling the lever frames themselves. Rather like a game of chess, it takes forward planning and a great deal of skill. Trains can’t crash into each other as the Gauge 1 model railway layout is split into many short lengths (blocks) of track, and interlocking means that only one train can be signaled into a block at a time. This is just how real trains on Network Rail operate. The Signalman can see the location of the trains via the overhead illuminated track plan, or his computer monitor for more accuracy.

You’ll see 23 levers on the L-frame; black ones are points and red ones are signals. As a general rule, a point lever is pulled first, and then the corresponding signal lever is then pulled. This signals to the ‘driver’ of the model railway train to proceed over the point and into the next section.

There are occasionally accidents and incidents on the Gauge 1 railway - usually caused by small hands getting too close to the trains!

Most visitors are unaware of the technology that goes in to running this incredible trainset – so stop a while at the Signal Box and take a look at the trains and equipment. Any duty Signalman will be happy to talk to you more about it. We’re jolly proud of it all and love to share our enthusiasm!

Construction

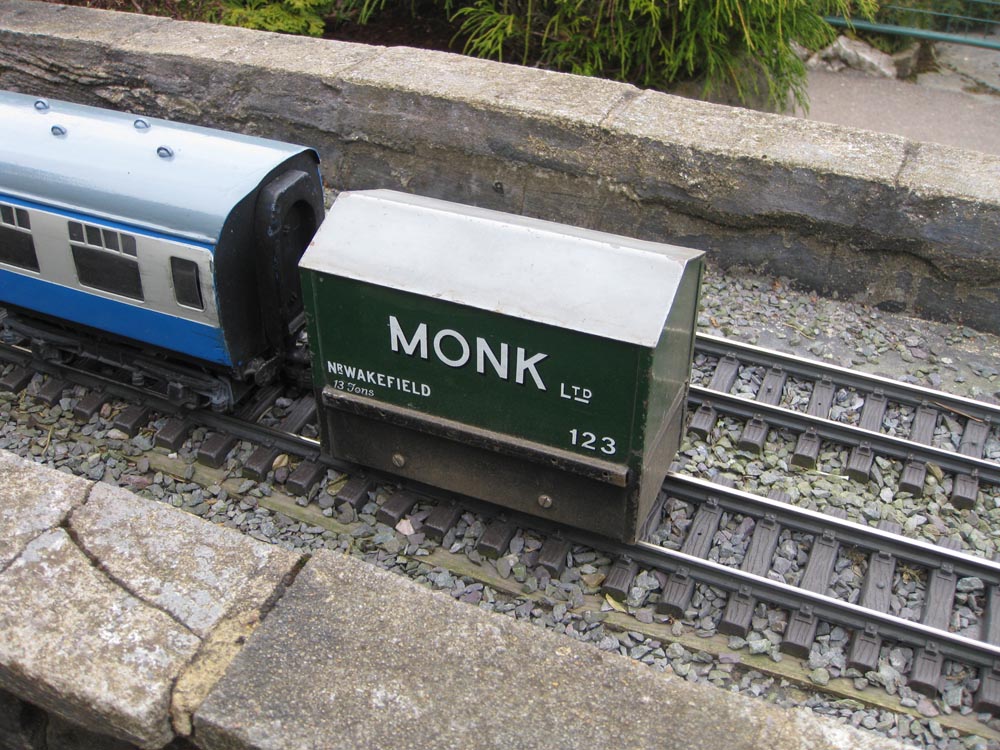

The present network is laid with LGB ‘G-scale’ track, with points built by ourselves to fit the required standard gauge radii. G-scale track is the same gauge as ‘Gauge 1’ (45mm between the rails) but is coarser and more durable. The model trains are built to Gauge 1 standards, where 10mm equals 1 foot, or approx 1:32 scale. If you’ve read this far then you’re probably a real railway enthusiast; so you’ll also notice that the rest of the village is at 1:12 to 1:15 scale. But like all true railwaymen, we believe that whatever looks right, is right. And it seems to look just about right, after all these years.

All locos and stock (with a few exceptions) have been built by Bekonscot staff to our very specific requirements. They are built with very strong metal chassis and handbuilt bodies from scratch components.

Launch Construction gallery Launch Construction galleryThe track is laid on a cast concrete base, with wood blocks floated in to provide anchor points. Notable engineering features on the line include the stone and metal scaled-down replica of Sydney Harbour Bridge over Alexandra Lake (named after the princess, whose favourite place to visit was Bekonscot), and the Manor House Tunnel (scale 1500 feet long) which is formed from large bore concrete pipes. Derailments inside can cause delays to the services on the Evenlode Branch, but provide an interesting spectacle for visitors!

The railway has run every year since 1929 in all weathers - even in the snow - despite its full-size counterparts seemingly failing as soon as the “wrong sort of leaves” hit the tracks. The durability and reliability of the BMR is testament to the great skill and loving care lavished upon it by successive generations of staff.