Technical Info

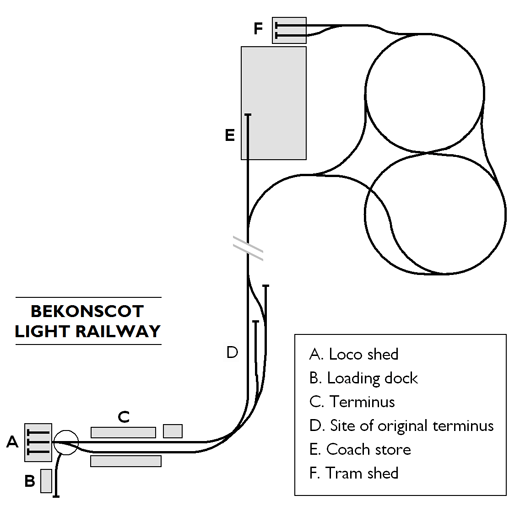

Operation is relatively simple; either one or two-train operation. One member of staff drives and performs the run-round operation, whilst the other takes money and explains the safety precautions. With two trains working, there are two drivers and one station master.

A full train will depart from the terminus and proceed around the circuit. Meanwhile the second train is loaded at the station. By the time this train is ready to depart, the first train will be on its way back and will wait in the old station passing loop for the second train to pass. Once the second train has disappeared off up the line, the first train is given the signal to return into the terminus and reload. A constant stream of passengers between 11am and 4:30pm ensures that trains depart almost constantly – in almost all weathers!

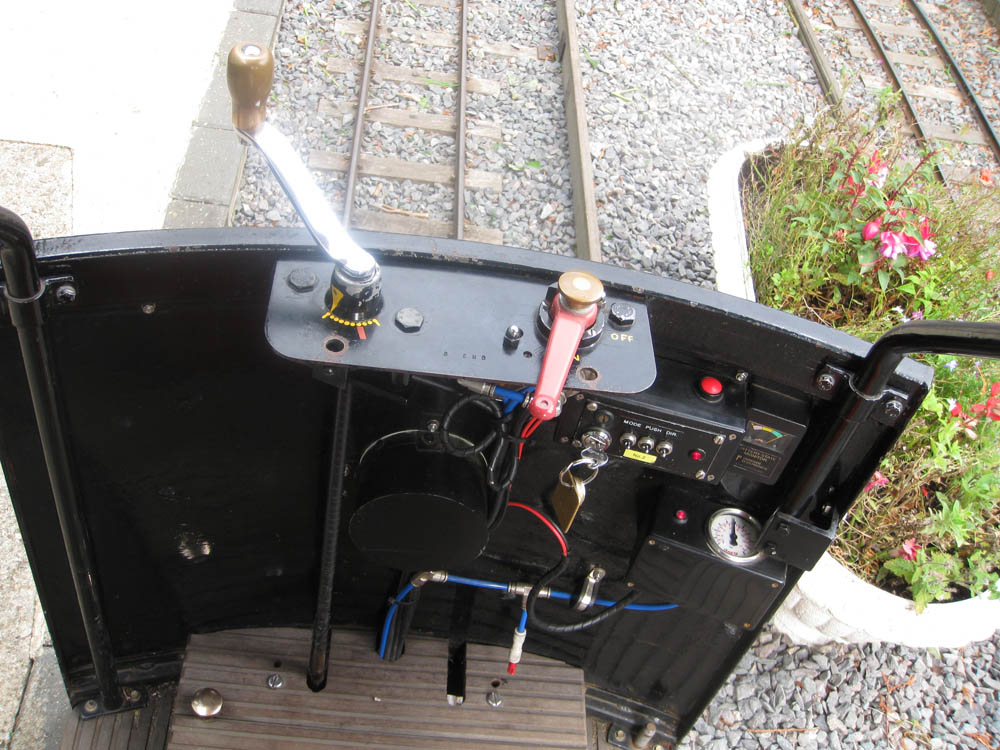

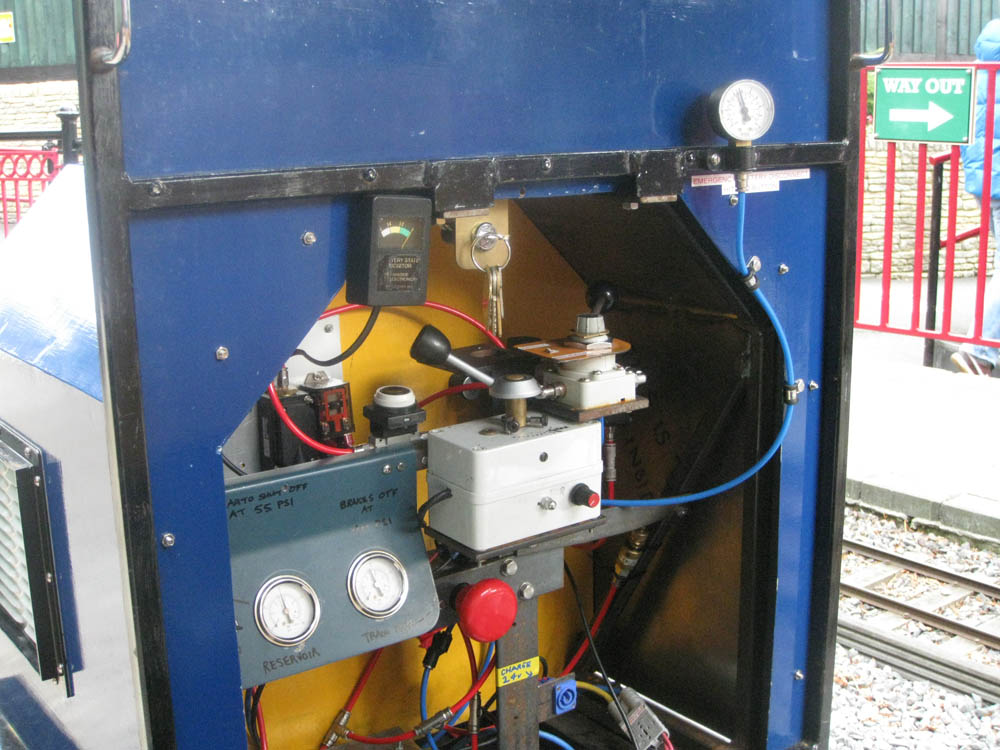

The points in the terminus are controlled pneumatically, as is the locking mechanism for the traverser. All of the points around the main circuit are sprung to enable automatic operation; but the points around the station are also pneumatically controlled to give different route options. The turntable is locked into position using an ingenious collection of spare parts from our ex-BR Westinghouse “L” style lever frame; the majority of which is used daily on our Gauge 1 line.

Facts

- Gauge 7.25” gauge (i.e. 7.25 inches between the rails)

- Track length: 150m

- Trip length: 247m in approx 3 minutes

- Track weight: 2lb and 6lb per yard

- Minimum curve radius: 20 feet